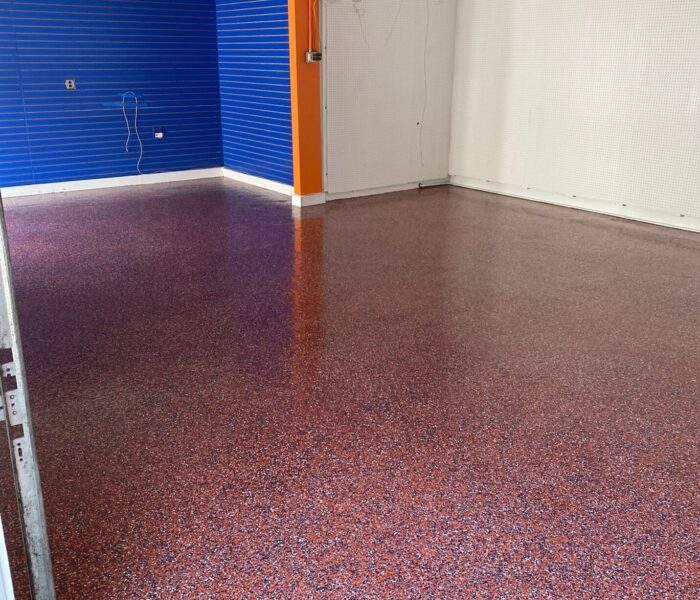

In this project, we completed anon-slip epoxy flooring and polyaspartic coatings for a 1,200 SF storage area adjacent to the homeowners garage floor.

The system we applied was an Elite Crete coating including epoxy base coat with a polyaspartic finish coat. We’ve used many industrial epoxy systems and keep returning to Elite Crete products.

We have found their systems perform the best in salty, humid areas like the Jersey Shore. The roads near the coast are sandy. Car tires pick up the salt from the road. Though you can’t see the salt, it’s there. The polyaspartic protective coating will withstand salt for years.

Epoxy Flooring Details

• Project – Storage Room

• Size – 1,200 sq. ft.

• Products Used – Elite Crete

• Type of System – Epoxy Flake floor w/ Polyaspartic Non-Slip Top Coat

• Time To Complete – 2 days

• Location – Toms River, Ocean County NJ

Frequently Asked Questions About Epoxy and Polyaspartic Floor Coatings

What is epoxy flooring?

The epoxy is made up of two main components – resins and hardeners. The result is a hard, durable, and resistant epoxy flooring that can withstand heavy traffic and wear. There are many types of epoxy depending on the surface requirement. They can range from thin epoxy paints to thick, high performance systems. Epoxy paints typically are 3 Mills thick. High performance, garage floor coatings range from 15-30 mils. Heavy duty epoxy coatings can exceed 100 mils.

What is a polyaspartic coating?

Polyaspartic is a type of aliphatic polyurea, a subcategory of polyurethane. It’s a high-performance coating that’s known for its fast curing time, UV stability, and resistance to chemical abrasion. Polyaspartic coatings also provide excellent color and gloss retention.

What is the lifespan of epoxy and polyaspartic floor coatings?

With proper installation and regular maintenance, epoxy floors can last 10 to 20 years. Polyaspartic coatings, due to their superior resistance to UV radiation and chemical abrasion, can also last equally long if not longer.

What type of maintenance do these coatings require?

Both epoxy and polyaspartic floors are relatively low maintenance. Regular sweeping and occasional mopping with a gentle cleanser are typically all that’s needed to keep the floor clean. They are resistant to stains and spills which can be easily wiped up.

Can these coatings be used on any type of floor?

Epoxy flooring and polyaspartic coatings are most commonly used on concrete floors but can be applied to other types of surfaces. However, the condition of the floor, such as its moisture content and the presence of any oil or grease, can affect the adhesion of the coating.

How long does it take to install these floor coatings?

The installation time can vary depending on the size of the space, the condition of the existing floor, and the specific requirements of the project. However, as an example, a typical garage floor can be completed in 2-3 days.

Are epoxy and polyaspartic coatings slip-resistant?

Yes, both types of coatings can be made slip-resistant by adding aggregates or other types of media to the top layer of the coating. This makes them a great choice for spaces where safety is a concern.

Can these coatings be used outdoors?

While epoxy coatings can be used outdoors, they may yellow or chalk when exposed to sunlight over time. Polyaspartic coatings, on the other hand, are UV stable, making them a better choice for outdoor applications.

What types of designs and colors are available?

Both epoxy and polyaspartic floor coatings can be customized in a variety of colors, patterns, and designs. You can choose from solid colors, flake systems for a terrazzo-like appearance, or even metallic finishes for a more unique look.

Are epoxy and polyaspartic coatings environmentally friendly?

Both epoxy and polyaspartic coatings are considered to be more environmentally friendly than many traditional types of floor coverings. They do not require frequent replacement and do not contain harmful volatile organic compounds (VOCs).